Efficient inventory management is a cornerstone of corporate success, influencing cash flow, customer satisfaction, and overall operational efficiency. In this article, we explore the critical Key Performance Indicators (KPIs) that corporates should actively track to optimize their inventory management strategies. These KPIs provide valuable insights into the health of the supply chain, helping corporates make informed decisions that drive profitability and sustainable growth.

Inventory Turnover

The Inventory Turnover Ratio is a financial metric that measures the efficiency with which a company manages its inventory. It provides insights into how quickly a company is selling and replenishing its inventory during a specific period. The ratio is crucial for assessing the effectiveness of inventory management, as it directly impacts a company’s cash flow, profitability, and overall financial health.

![]()

Where:

- Cost of Goods Sold (COGS): This represents the direct costs associated with the production or purchase of goods that were sold during the period. It includes expenses such as raw materials, labor, and manufacturing overhead.

- Average Inventory: This is the average value of the inventory over a specific period, usually calculated by taking the sum of the beginning inventory and ending inventory for the period and dividing it by 2.

Days Inventory Outstanding (DIO)

Days Inventory Outstanding (DIO), also known as Days Sales of Inventory (DSI), is a financial metric that measures the average number of days a company takes to sell its entire inventory during a specific period. DIO provides insights into how efficiently a company manages its inventory and the speed at which it is able to turn its inventory into sales. This metric is crucial for assessing inventory management practices, optimizing cash flow, and gauging the effectiveness of a company’s supply chain.

The DIO is expressed in terms of days and indicates the average number of days it takes for a company to sell its entire inventory. A lower DIO suggests that the company is selling its inventory more quickly, which is generally favorable for cash flow and operational efficiency. On the other hand, a higher DIO may indicate slower inventory turnover, potentially leading to increased holding costs and the risk of obsolescence.

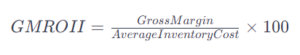

Gross Margin Return on Inventory Investment

Gross Margin Return on Inventory (GMROII) is a critical financial metric that plays a pivotal role in evaluating the profitability of a company’s inventory management. This key performance indicator (KPI) provides valuable insights into how efficiently a company is generating gross profit relative to its investment in inventory. In essence, GMROII assesses the return on every dollar invested in inventory, helping businesses make informed decisions about pricing, product assortment, and inventory levels.

The GMROII formula is relatively straightforward, making it a powerful tool for financial analysis. The formula is expressed as:

Where:

- Gross Margin represents the difference between total sales revenue and the cost of goods sold (COGS).

- Average Inventory Cost is the average value of the inventory over a specific period.

Also Read: Key KPIs For Effective DSO Management

Importance of Cash Conversion Cycle

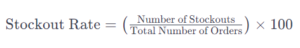

Stockout Rate

The Stockout Rate is a key performance indicator (KPI) that measures the percentage of time a company experiences a shortage of products or inventory, resulting in an inability to fulfill customer orders. This metric is essential for assessing the effectiveness of inventory management and the impact of stockouts on customer satisfaction and overall business performance.

Stock out rate is calculated as

Where:

- Number of Stockouts: This represents the total count of orders during a specific period where the company did not have sufficient inventory to fulfill the customer’s request.

- Total Number of Orders: This includes all orders placed during the same period, regardless of whether they were fulfilled or resulted in stockouts.

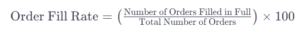

Order Fill Rate

The Order Fill Rate is a key performance indicator (KPI) that measures the percentage of customer orders that a company successfully fulfills in their entirety without any stockouts or backorders. This metric is crucial for assessing the effectiveness of a company’s inventory management and order fulfillment processes, providing insights into the company’s ability to meet customer demand promptly and completely.

Where:

- Number of Orders Filled in Full: This represents the count of orders that were completely fulfilled without any stockouts or items on backorder.

- Total Number of Orders: This includes all customer orders received during a specific period, regardless of whether they were filled in full or not.

The Order Fill Rate is expressed as a percentage and indicates the proportion of orders that were successfully fulfilled without any issues. A high order fill rate is generally considered favorable, reflecting a company’s commitment to meeting customer expectations and minimizing disruptions in the order fulfillment process. On the other hand, a lower order fill rate may suggest challenges in inventory management, demand forecasting, or supply chain efficiency.

Backorder Rate

The Backorder Rate is a key performance indicator (KPI) that measures the percentage of customer orders that cannot be fulfilled immediately due to insufficient inventory, leading to a situation where items are placed on backorder. This metric is crucial for assessing the effectiveness of a company’s inventory management and order fulfillment processes, as well as understanding the impact of stockouts on customer satisfaction and overall business performance.

![]()

Where:

- Number of Backordered Items: This represents the count of items that were not available in the company’s inventory to fulfill customer orders and were, therefore, placed on backorder.

- Total Number of Ordered Items: This includes the total count of items that customers ordered during a specific period, regardless of whether they were available or placed on backorder.

The Backorder Rate is expressed as a percentage and provides insights into the extent to which a company is unable to meet immediate customer demand due to inventory shortages. A lower backorder rate is generally considered favorable, indicating that the company can fulfill most customer orders promptly. Conversely, a higher backorder rate may suggest challenges in inventory management, procurement, or supply chain efficiency.

Carrying Cost of Inventory

The Carrying Cost of Inventory, often referred to as holding cost, is the total cost incurred by a business to hold and store its inventory over a specific period. Carrying costs represent the expenses associated with maintaining and storing inventory, and they play a significant role in inventory management decisions. Calculating the carrying cost of inventory helps businesses assess the financial impact of holding onto products and guides them in making strategic decisions about inventory levels and ordering practices.

The carrying cost of inventory includes various components, and the specific elements may vary depending on the industry and business practices. Common components of carrying cost include storage cost, Insurance, inventory handling cost, Security cost, Deterioration and Obsolescence Costs and opportunity cost (ie; cost of capital)

Obsolete Inventory Rate

The Obsolete Inventory Rate is a key performance indicator (KPI) that measures the percentage of a company’s inventory that is considered obsolete or no longer sellable. Obsolete inventory refers to items that are outdated, expired, or have become irrelevant due to changes in market demand, technological advancements, or other factors. Calculating the obsolete inventory rate helps businesses assess the efficiency of their inventory management practices and make informed decisions about inventory write-offs and adjustments.

![]()

Where:

- Value of Obsolete Inventory: The value of inventory that is considered obsolete.

- Total Inventory Value: The overall financial value of the company’s inventory.

Cycle Count Accuracy

Cycle Count Accuracy assesses how closely the physical inventory matches the recorded inventory levels. Regular cycle counts help identify discrepancies and improve data accuracy, reducing the risk of stockouts or overstocks due to inaccurate information.

It is a key performance indicator (KPI) that measures the precision and reliability of a company’s cycle counting process in managing inventory accuracy. The accuracy of these cycle counts is crucial for maintaining an up-to-date and reliable inventory record, which, in turn, impacts various aspects of supply chain management, customer satisfaction, and financial reporting.

![]()

Where:

- Number of Correctly Counted Items: The count of inventory items that were accurately counted during the cycle counting process.

- Total Number of Items Counted: The total count of items that were included in the cycle counting process.

Supplier Lead Time

Supplier Lead Time, also known as procurement lead time or vendor lead time, is the duration it takes for a supplier to fulfill an order from the moment the order is placed until the goods are received and available for use or further processing by the buyer. This lead time is a critical factor in supply chain management and impacts a company’s ability to meet customer demand, maintain optimal inventory levels, and plan production schedules effectively.

Perfect Order Rate

Perfect Order Rate is a key performance indicator (KPI) that measures the percentage of customer orders that are successfully delivered to the customer without any errors or defects. This metric provides insights into the overall efficiency and reliability of a company’s order fulfillment process, reflecting its ability to meet customer expectations and deliver a seamless customer experience. The Perfect Order Rate considers various elements of order fulfillment, including on-time delivery, accurate product selection, complete order fulfillment, and proper documentation.

![]()

Where:

- Number of Perfect Orders: The count of customer orders that were fulfilled without any errors or defects, meeting all customer requirements.

- Total Number of Orders: The overall count of customer orders during a specific period.

In conclusion, strategic inventory management is a dynamic process that requires continuous monitoring and adaptation. The KPIs outlined above offer valuable insights into various facets of inventory management, from turnover efficiency to order fulfillment accuracy. Corporates that prioritize the tracking of these KPIs can make informed decisions, optimize their supply chains, and position themselves for sustained success in the competitive business landscape. Embracing a data-driven approach to inventory management is not only a strategic advantage but a key enabler of operational excellence and profitability.

Pingback: Understanding Perfect Order Rate - corpfinanceinsights.com

Pingback: Efficient Inventory Management: A Key to Enhancing Company Performance - corpfinanceinsights.com

Pingback: 10 KPIs for Effective Accounts Payables Management - corpfinanceinsights.com

Pingback: Vendor Managed Inventory (VMI) - corpfinanceinsights.com

Pingback: Inventory Management Strategies - corpfinanceinsights.com