Efficient inventory management is pivotal for businesses to maintain a delicate balance between meeting customer demand and controlling costs. One of the fundamental concepts in this domain is Economic Order Quantity (EOQ). EOQ is a mathematical formula used to determine the optimal quantity of inventory a company should order or produce to minimize total inventory costs while meeting customer demand effectively.

What is Economic Order Quantity (EOQ)?

Economic Order Quantity (EOQ) is a formula used to determine the ideal order quantity that minimizes total inventory costs. It balances the costs associated with ordering and holding inventory. EOQ provides insights into how much inventory a company should order or produce at one time to minimize costs related to ordering, holding, and shortage.

How is Economic Order Quantity (EOQ) Calculated?

The EOQ formula takes into account two cost components:

- Ordering Costs: These are the costs incurred each time an order is placed, including administrative expenses, transportation costs, and setup costs.

- Holding Costs: Also known as carrying costs, these are expenses incurred for holding inventory over a specific period, including warehousing expenses, insurance, obsolescence, and the cost of capital tied up in inventory.

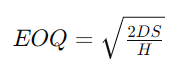

The formula for EOQ is derived from the balance between ordering costs and holding costs:

Where;

- D represents the annual demand (in units).

- S represents the ordering cost per order.

- H represents the holding cost per unit per year.

By calculating EOQ, a company can find the optimal order quantity that minimizes the sum of ordering and holding costs.

Examples of Economic Order Quantity (EOQ)

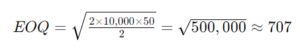

Let’s illustrate EOQ with a hypothetical example: Suppose a retail store sells 10,000 units of a particular product annually, with an ordering cost of $50 per order and holding cost of $2 per unit per year.

- S = $50

- H = $2

Using the EOQ formula:

So, the optimal order quantity (EOQ) for this example would be approximately 707 units.

Industries Adopting EOQ

Economic Order Quantity (EOQ) is a widely adopted concept across various industries, including manufacturing, retail, wholesale, and distribution. Any business that deals with inventory management can benefit from implementing EOQ principles. Some industries where EOQ is commonly applied include:

- Retail: Supermarkets, convenience stores, and online retailers use EOQ to determine how much stock to order to meet customer demand without excessive holding costs.

- Manufacturing: Manufacturers use EOQ to optimize production schedules and raw material orders, ensuring that they have enough inventory to fulfill orders while minimizing storage costs.

- Healthcare: Hospitals and clinics use EOQ to manage medical supplies efficiently, ensuring they have enough stock of essential items without overstocking and incurring unnecessary costs.

- Automotive: Car dealerships and manufacturers use EOQ to manage their inventory of spare parts and components, optimizing costs while ensuring timely availability for repairs and maintenance.

Advantages of EOQ

The Economic Order Quantity (EOQ) is a crucial concept in inventory management, designed to optimize the balance between ordering and holding costs. It’s based on the idea that there is an optimal quantity of inventory to order, which minimizes total inventory costs. While EOQ has its limitations and complexities, its advantages are significant and can positively impact businesses across various industries. Here, we’ll delve into the advantages of EOQ in detail:

- Cost Efficiency: One of the primary advantages of EOQ is its ability to minimize total inventory costs. By determining the optimal order quantity, businesses can reduce both holding costs (costs associated with storing inventory) and ordering costs (costs associated with placing orders), thus maximizing cost efficiency. This ensures that capital is not tied up unnecessarily in excess inventory or lost due to frequent orders.

- Optimized Inventory Levels: EOQ helps in maintaining optimal inventory levels. By calculating the EOQ, a company can ensure that it holds enough inventory to meet customer demand without overstocking. This prevents stockouts, which can lead to lost sales and dissatisfied customers, while also avoiding the costs of holding excess inventory.

- Reduction in Stockouts and Backorders: EOQ minimizes the likelihood of stockouts or backorders by ensuring that enough inventory is on hand to meet demand during lead times. This improves customer satisfaction and helps maintain a positive reputation for the business.

- Streamlined Ordering Process: Another advantage of EOQ is its ability to streamline the ordering process. By determining the optimal order quantity, businesses can establish regular ordering schedules, reducing the administrative burden associated with frequent order placements. This can lead to operational efficiencies and cost savings in terms of labor and paperwork.

- Quantity Discounts Utilization: EOQ facilitates leveraging quantity discounts offered by suppliers. Since EOQ calculates the optimal order quantity, businesses can take advantage of bulk purchasing discounts without overordering. This enables businesses to secure lower purchase prices, leading to potential cost savings and improved profit margins.

- Improved Cash Flow: Maintaining optimal inventory levels through EOQ helps in better cash flow management. By minimizing excess inventory, businesses can allocate their capital more efficiently to other areas of operations, such as investment in growth initiatives or debt repayment.

- Enhanced Production Planning: For manufacturing businesses, EOQ can aid in production planning by ensuring that raw materials or components are ordered in the right quantities at the right time. This prevents production delays caused by shortages or overstocking, leading to smoother operations and reduced idle time.

- Risk Mitigation: EOQ can help mitigate risks associated with inventory management. By optimizing inventory levels and order quantities, businesses reduce the likelihood of obsolescence, shrinkage, or spoilage, thus minimizing potential losses.

- Decision Support Tool: EOQ serves as a valuable decision support tool for managers. It provides actionable insights into inventory management, helping managers make informed decisions regarding ordering policies, inventory investment, and supply chain optimization.

- Competitive Advantage: Implementing EOQ effectively can provide a competitive advantage in the marketplace. By optimizing inventory management practices, businesses can offer better customer service, faster delivery times, and competitive pricing, thereby attracting and retaining customers.

Limitations of EOQ

While Economic Order Quantity (EOQ) is a valuable tool for optimizing inventory management, it’s essential to recognize its limitations and challenges. Understanding these limitations can help businesses make more informed decisions and complement EOQ with other inventory management techniques where necessary. Here are some key limitations of EOQ:

- Assumption of Constant Demand: EOQ assumes that demand for the product is constant and uniform over time. However, in reality, demand may fluctuate due to various factors such as seasonality, market trends, or changes in customer preferences. Thus, EOQ may not be suitable for products with unpredictable or highly variable demand patterns.

- Assumption of Constant Lead Time: Similarly, EOQ assumes a constant lead time for replenishing inventory. In practice, lead times may vary due to factors like supplier reliability, transportation delays, or production disruptions. Fluctuations in lead times can impact inventory levels and reorder points, affecting the accuracy of EOQ calculations.

- Inflexibility with Price Fluctuations: EOQ calculations are based on fixed unit costs for both ordering and holding inventory. However, in reality, prices may fluctuate due to changes in supplier pricing, currency exchange rates, or market conditions. Significant price fluctuations can affect the economic order quantity and may require frequent recalculations to maintain cost efficiency.

- Ignored Storage Constraints: EOQ assumes unlimited storage capacity, overlooking practical constraints such as warehouse space or storage facilities. Businesses with limited storage space may not be able to accommodate the EOQ quantity, leading to additional holding costs or the need for alternative storage solutions.

- Overlooked Inventory Holding Costs: While EOQ considers holding costs associated with inventory storage, it may not capture all relevant holding costs accurately. For example, EOQ typically calculates holding costs based on average inventory levels, overlooking costs related to inventory obsolescence, spoilage, or insurance. These additional holding costs can impact the overall cost-effectiveness of EOQ.

- Complexity of Calculations: EOQ calculations involve complex mathematical formulas, requiring accurate inputs such as demand rate, ordering cost, and holding cost per unit. Small errors in input data or assumptions can lead to significant discrepancies in EOQ results. Moreover, recalculating EOQ frequently to accommodate changes in demand or costs can be time-consuming and resource-intensive.

- Limited Application to Multi-Product Environments: EOQ is primarily designed for single-product inventory management. In multi-product environments where businesses deal with diverse product lines or SKU (Stock Keeping Unit) portfolios, applying EOQ individually to each product may not be practical. Alternative approaches such as ABC analysis or inventory optimization models may be more suitable for managing inventory across multiple products efficiently.

- Lack of Consideration for Demand Uncertainty: EOQ does not explicitly consider demand uncertainty or variability in its calculations. High demand variability can increase the risk of stockouts or excess inventory, undermining the effectiveness of EOQ-based inventory policies. Businesses operating in volatile or uncertain markets may need to supplement EOQ with demand forecasting techniques or safety stock buffers to mitigate these risks.

- No Consideration for Strategic Objectives: EOQ focuses primarily on minimizing inventory costs without considering broader strategic objectives such as service level targets, sustainability goals, or supply chain resilience. While EOQ can help optimize cost efficiency, businesses must align inventory management decisions with their strategic priorities to achieve long-term success.

- Dynamic Nature of Business Environment: Finally, the business environment is dynamic, characterized by constant change and uncertainty. Factors such as market trends, technological advancements, regulatory requirements, or competitive pressures can influence inventory management practices over time. EOQ, as a static model, may struggle to adapt to these dynamic conditions without regular review and adjustment.

Conclusion

Economic Order Quantity (EOQ) is a valuable tool for businesses seeking to optimize their inventory management processes. By calculating the optimal order quantity, companies can minimize total inventory costs while ensuring adequate stock levels to meet customer demand. While EOQ has its limitations, its widespread adoption across industries underscores its importance in achieving operational efficiency and cost savings. Businesses that effectively implement EOQ principles can gain a competitive advantage in today’s dynamic marketplace.